Lahdyfhoe APMT1604PRER Gbj Apmt1604 Pder Apmt160408Pder Milling Inserts Turning Inserts Cutting Tools

- Model - APMT1604 PDER R0.8 , Coating - NANO CVD, Material - Carbide, Heat treatment makes inserts harder

- Application - this kind of APMT1604 milling inserts are especially suitable for processing hard steel parts (eg. 4140 alloy steel ) and stainless iron, suitable for material of HRC35 - HRC50perform pretty well on quenched harden steel. Installed on 400R Series End milling holder

- Nano Coating - CVD , APMT1604PDER are coated by NANO blue coating, which is a kind of new coating technology. After repeated tests, we can ensure that the apmt1604pder milling blades have strong impact resistance, good versatility with high precision, high finish and high wear resistance.

- Advantages - The apmt1604pder milling carbide inserts have composite matrix with the AlTiN coating of composite multilayer structure , which greatly prolongs service life of cutting tool . Tools has super strong film-base bonding force and extremely low friction coefficient

- Package includes - 10pcs APMT1604PDER carbide inserts

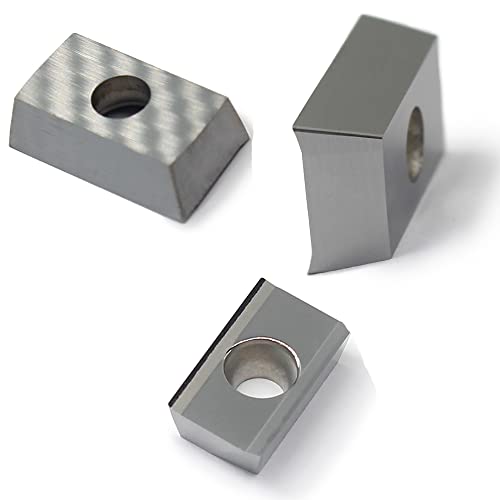

Oscarbide 10 Carbide Milling Inserts Tpcn32Pdtr Tpg32 Mutilayer Coated Carbide Turning Inserts

- TPCN32PDTRTPCN1603PDTR Indexable Carbide Milling Insert 1/8 inch Thick,11 degree relief angle.

- Material - made of solid carbide with mutilayer coated, offer long life and faster cutting speed, low friction coefficient, good wear resistance

- For turning and milling carbon and alloy steels, tools steel and stainless steel

- Screw on triangle style insert with a chipbreaker

- 10 pieces per box, provides longer tool life than uncoated grades

Oscarbide 10 Carbide Inserts Apkt1604 Tialn Coated Indexable Milling Inserts Apkt Style,10 Piece/Box

- APKT 1604 carbide turning inserts,85 degrees parallelogram,Relief Angle 11 degrees,nose radius 1/32".

- Made of Tungsten Carbide,TiAlN Coated ,the cutting speed are 4-7 time faster than generic steel,and Sharpened on a diamond wheel to make it longer tool life, providing you a better experience and durable use and Better cut

- Designed for cast iron and non-ferrous materials,good for both finishing and roughing

- Used for indexable face mill and end mill,Performing square milling and side milling,ramping milling, helical milling, slotting milling, plunging milling.

- These Insert fit for our Carbide Indexable End Mills and other same size indexable end mills, please search B07SG8JKDS or B099WPXW29 to buy this indexable end mills

Rhfgyy 10Pcs Apkt1135 + Apkt1604 Pdfr Face Milling Inserts Aluminum Cutting Inserts Aluminum Cutting Tool Turning Tool Cnc Tools Al+Tin Alloy Wood

- Model size - APKT1135 +APKT1604 milling inserts for aluminum

- Using imported substrates,Alloy substrates, H01 coating ,thermal stability, chip and non-stick blade

- Edge sharpness, good toughness,smoothing cutting and high durability

- Processing range - JW40-aluminum alloy general processing and non-ferrous metal

- Package includes - 5pcs APKT1135PDFR-MA + 5pcs APKT1604PDFR-MA

Satpistoul MILLING INSERTS001 Apmt1604Pder Carbide Inserts

- Superior Milling Performance - The APMT1604 PDER carbide inserts are perfect for fine and semi-fine milling of stainless steel materials. With smooth chip removal, high hardness, and exceptional heat resistance, these milling inserts ensure efficient and precise milling operations.

- High-Precision and Durability - Featuring high-precision passivation treatment and advanced coating processes, these carbide apmt1604 tin coated inserts boast a long service life. The titanium-plated hard alloy construction provides superior wear resistance and a sharp cutting edge for fast and accurate cutting.

- Comprehensive Specifications - Model - The model of this lathe milling inserts - Dual-edge APMT1604 PDER;Coating - CVD;Material - Carbide;I.C (d) - 0.366 inch (9.3 mm);Thickness (s) - 0.187 inch (4.75 mm);Hole (d1) - 0.173 inch (4.4 mm);Nose Radius (r) - 1/32 inch (0.8 mm);Nose Angle - 85;Relief Angle - 11 Suitable for both finishing and roughing applications.

- Versatile Applications - Designed for processing steel parts (e.g., 4140 alloy steel) and stainless iron (e.g., 304 stainless steel), these lathe holder milling inserts are ideal for materials with hardness ranging from HRC 15 to HRC 45. Compatible with 300R Series End Milling Holders, this lathe turning milling carbide insert are perfect for indexable face mills, end mills, peripheral milling, ramping milling, helical milling, slotting milling, and plunging milling.

- Enhanced Performance with CVD Coating - The CVD coating on these turning milling carbide inserts provides strong impact resistance, high precision, and excellent finish quality. The combination of a carbide matrix and AlTiN coating with a composite multilayer structure ensures prolonged tool life, strong film-base bonding, and a low friction coefficient, making them ideal for high-quality and efficient steel and stainless steel processing.

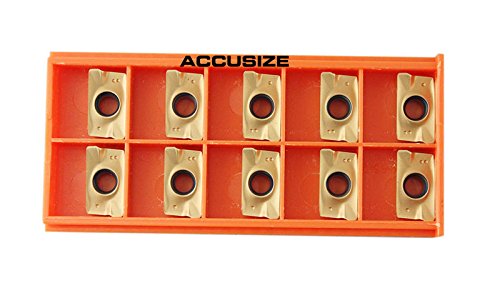

Accusize Industrial Tools 0056-1604 Apkt1604 Tin Coated Carbide Inserts

- Product Details - Item No - 0056-1604, Insert - APKT1604, ISO Designation - APKT160408.

- Coating - TiN Coated for enhanced durability and machining speed.

- Specifications - I.C. 0.366", Thickness 0.208", Hole 0.173", Radius 1/32".

- Package - 10 pcs per case, 1 case, 10 pieces in total.

- Material Compatibility - Ideal for machining steel and proven for stainless steel.

- Applications - Suitable for shoulder milling, face milling, profile milling, groove milling, parting off, chamfer milling, turn milling, gear machining, holes and cavities/pocketing.

- Technical Excellence - Features an 11 relief angle and ISO-compliant screw holes for stability and smooth operation.

- Precision Design - Includes precision-molded I.C. and positive chipbreaker with sharp, honed edges for clean, efficient cuts.

- Extended Tool Life - Equipped with 4 cutting edges, minimizing tool changes in high-volume operations.

- High-Performance Milling - Supports medium to high cutting speeds for a wide range of applications from roughing to finishing.

Oscarbide 10 Carbide Inserts Apkt11T308 Milling Inserts Apkt Style Inserts

Linggan SEHT1204AFSN-X45 NC325 10Pcs Seht 43 Afsn Carbide Insert Face Mill Seht1204 X45 Nc325 Lathe Milling Cnc Tools Milling Cutter

- It Is Processed By Imported Technology And Has The Advantages Of High Hardness, Strong Wear Resistance, High Smoothness, Not Easy To Stick To The Knife, And Smooth Chip Removal.

- Different R Angles Can Meet Your Needs For Fine Turning Or Rough Turning, Reduce Cutting Resistance, And Achieve Sharp Cutting.

- The Turning Is Light And Fast, And The Advanced Coating Process Is Sprayed By The 1000-Degree Stress Accumulation Method, The Coating Is Thicker, And The Cutting Edge Is Passivated, Strong And Durable.

- The Unique Groove Design Can Make Chip Removal Faster And Smoother, So As To Ensure That The Excrement Will Not Scratch The Surface Of The Product!

- The Blade Is Both Sharp And Thick, So That It Can Realize The Ideal Processing That Is Fast And Not Easy To Stick To The Knife, High Smoothness And Not Easy To Break.

Aszlbym 01 11Pcs Rpmt10T3 Moe R5 Indexable Carbide Milling Inserts Blade Milling Cutter

- PACKAGE INCLUDES - You will receive 1pc SRDPN1616H10 5/8/16mm shank diameter carbide lathe milling tool holder , 11pcs RPMT10T3 MOE indexable carbide milling inserts cutters and 1pc T15 wrench.

- Material - The SRDPN1616H10 5/8 inch lathe milling tool holder material is 40Cr steel, it has the characteristics of durability, sturdiness and stability, and good anti-rust performance. The RPMT10T3 MOE indexable milling inserts cutter material is carbide, and the coating is CVD Al2O3 TICN, It has good toughness, wear resistance and high temperature resistance, the milling insert can be used for milling cast iron, steel parts and stainless steel.

- Milling tool holder cutter size - Shank Diameter ( lengthwidth ) - 5/8"*5/8"(16mm*16mm) ; Overall Length - 100 mm 3.93 inch .

- RPMT10T3 MOE carbide milling insert size - Insert Style - RPMT , thickness - 0.156 inch 3.97mm , diameter - 0.393 10mm, P=11 degree.

- Easy to store - the milling tool holder and carbide milling inserts are packed in a plastic container, safe and easy to store, please rest assured to buy!

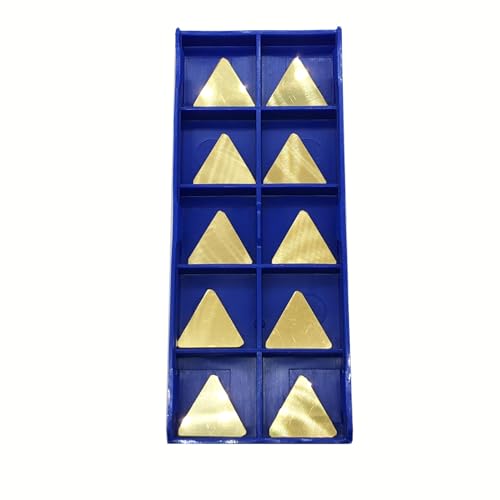

Linzuan TCMT16T304/32.51 TCMT16T308/32.52 20Pcs Tcmt32.51 Tcmt32.52 Tcmt16T304 Tcmt16T308 Carbide Inserts Turning Inserts

- 1. Model - TCMT16T304/32.51 TCMT16T308/32.52

- 2.package - 5pcs TCMT32.51 bronze +5pcs TCMT32.52 bronze +5PCS TCMT32.51 yellow +5pcs TCMT32.52 yellow

- 3.Suitable for finishing and semi-finishing of various steel, stainless iron and cast iron workpieces

- 4. Wear-resistant and heat-resistant, not easy to stick to the holders or workpieces or break up

- 5.Advantage - Wear-resistant and heat-resistant, not easy to stick to the holders or workpieces or break up.Vacuum hardening, exquisite craftsmanship, easy cutting

Lahdyfhoe UFBAOBN86542 Gbj 1 Inch Shank R8 Face Milling Cutter Arbor End Mill Tool Holders Withtpkn1603Pdskr Triangle Inserts Carbide Inserts Indexable Milling Inserts

- Size - TPKN1603PDSKR 301 .Inserts use high hardness substrate, suitable for medium speed and high speed; light and heavy load milling of low alloy steel and non-alloy steel, and can also be used for milling under the condition of price difference

- Material - made of solid carbide with tin coated, offer long tool life and faster cutting speed, low friction coefficient, good wear resistance

- Thick AL2O3 coating extends the life of the inserts working in high temperature. The first choice for steel processing from finishing to rough machining.

- It has strong resistance to plastic deformation and edge strength.High-hardness processing, stable performance, sturdiness and durability.Used for turning and finishing on a wide range of materials

- Designed for Steel, cast iron and non-ferrous materials

Feleolibe MG115 Carbide Turning Inserts Apkt1604 Indexable Milling Inserts,10Pieces/Pack

- Product size - Carbide insert APKT1604PDER-G2 H01, inner diameter 0.364", thickness 0.187", hole diameter 0.173", radius 1/32".

- Material - Alloy material, imported coating technology, good cutting stability, high wear resistance.

- Features - Sharp edge, wear-resistant and anti-chipping, smooth chip removal.

- Adaptation Scope - Designed for aluminum processing, used for indexable face milling cutter and end milling cutter, for square milling and side milling.

- Package Includes - 10Pcs Carbide Inserts APKT1604PDER-G2 H01.

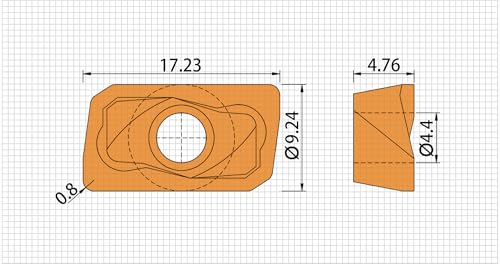

Axolotl.Ctㅤ RY- APMT160408PDR-GWCT Cnc Carbide Milling Inserts Apmt160408Pdr

- 1.Size - APMT160408PDR, (I.C) - 9.35mm, Radius(R) - 0.8mm, Longth(L) - 17.35mm, Thickness(S) - 5.2mm, Dimension(d) - 4.4mm.

- 2.Nano Coating - PVD Coating grey color, a nanocomposite coating of a AITiSi base, high temperature stability, good hardness.

- 3.Material - Long processing life, high cost performance, with better working, suitable for stailess steel, carbon steel and heat-resistant steel processing.

- 4.Applications - Provide the perfect smooth cutting. A high the thermal shock resistance, suitable for light interrupted cuts.

- 5.AXOLOTL.CT Tools can provide the highest working efficiency and optimal surface quality for customer.

- 6.Package - 10 pieces, easy to store.

Delitongude TI01 10Pcs Apkt1003Pdtr Cnc Lathe Indexable Solid Carbide Milling Turning Insert

- Superior Cutting Performance - Elevate your machining capabilities with our APKT1003PDTR inserts, designed for superior cutting performance in industrial applications, ensuring precise and efficient results.

- Versatile Applications - Engineered for versatility, the APKT1003PDTR inserts are suitable for a wide range of industrial uses, making them a reliable choice for machining different materials with precision and consistency.

- Tin is a universal PVD coating, which can improve tool hardness and have a high oxidation temperature. The coating can be used for high speed steel cutting tools or forming tools to obtain good machining results.

- Optimized Chip Evacuation - Experience smooth and efficient chip evacuation, reducing downtime and enhancing the overall efficiency of your machining operations. These inserts are engineered for optimal chip control.

- Cost-Effective Precision - Strike the perfect balance between precision and affordability. Our APMT160408 turning inserts deliver cost-effective solutions without compromising on the high standards required for industrial machining.

Cdbp APKT1003 Pdsr-30, Indexable Inserts

- Size - APKT1003, Width(I.W) - 0.2598 in, Longth(L) - 0.41 in, Radius(R) - 0.0157 in, Thickness(S) - 0.093in, Dimension(d) - 0.11in

- PVD Coating grey color, a nanocomposite coating of a AITiSi base, high temperature stability, good hardness. Small friction coefficient, reduce the adhesion between workpiece and insert cutting edge

- Suitable for stailess steel, carbon steel and heat-resistant steel processing

- When need excellent edge strength and high surface quality, provide the perfect smooth cutting. A high the thermal shock resistance, suitable for light interrupted cuts

- CDBP Tools developed a series of indexable milling inserts which can provide the highest working efficiency and optimal surface quality for customer

Fomasp APKT1003PDSR Fit For Lathe Milling Cutting Tools 10Pcs

- With a black PVD coating, this carbide blade is especially suitable for machining steel, stainless steel and cast iron materials, providing precise and efficient finishing results at low to medium cutting speeds, ensuring smooth surfaces and accurate dimensions.

- Size, (I.W) - 6.66mm, Radius(R) - 0.4mm, Longth(L) - 10.37mm, Thickness(S) - 3.5mm, Dimension(d)2.8mm

- This cutting steel uses PVD coating technology, especially the addition of TiAIN layer, its coating microhardness up to HV3200, showing excellent wear resistance, at the same time, it can withstand 400-500 high temperature environment, excellent heat resistance. After the coating treatment, the cutting edge is sharper, ensuring efficient cutting operations.

- This cutting steel has a long processing life and a very high cost performance.

- We have more than 15 years of experience in carbide blade production, with rich technical accumulation and professional knowledge, we continue to provide high quality, high performance carbide blade products to meet the various needs of customers.

Linggan 2020-9-30-10-10 Carbide Milling Insert Round Rpmw1003 Mo (R5) Cnc Milling Machine Indexable Milling Insert

- It Is Processed By Imported Technology And Has The Advantages Of High Hardness, Strong Wear Resistance, High Smoothness, Not Easy To Stick To The Knife, And Smooth Chip Removal.

- Different R Angles Can Meet Your Needs For Fine Turning Or Rough Turning, Reduce Cutting Resistance, And Achieve Sharp Cutting.

- The Turning Is Light And Fast, And The Advanced Coating Process Is Sprayed By The 1000-Degree Stress Accumulation Method, The Coating Is Thicker, And The Cutting Edge Is Passivated, Strong And Durable.

- The Unique Groove Design Can Make Chip Removal Faster And Smoother, So As To Ensure That The Excrement Will Not Scratch The Surface Of The Product!

- The Blade Is Both Sharp And Thick, So That It Can Realize The Ideal Processing That Is Fast And Not Easy To Stick To The Knife, High Smoothness And Not Easy To Break.

Zouzmin 10Pcs Apgt/Apmt1135Pder-G2 Milling Inserts

- Model - APGT1135PDFR-G2

- Mainly used for Aluminum alloyhardness - 20-110HB

- low cutting force,prolong the cutting edge service life during the continuous turning process of aluminum alloy

- High-strength design of main cutting edge.reduce cutting resistance and cutting load,lower temperature, smooth chip discharge which is conducive to chip control

- Package lncluded - 10pcs Aluminum insert (1 box).

Yufutol APKT11T308 10PCS Carbide Milling Inserts Apkt11T308 Tin Coated Lathe Carbide Inserts

- Insert - APKT11T308. coating - TiN, i.c - 0.256", thickness - 0.142", hole - 0.110", nose radius - 0.031", Relief Angle 11 degrees

- Suitable for both finishing and roughing, used for indexable face mill and end mill. Performing square milling and side milling

- Material - Solid Carbide. Coating - TiN coated for longer service life, wear resistance, more durable and sharp

- It has strong resistance to plastic deformation and edge strength.High-hardness processing, stable performance, sturdiness and durability

- Package - 10 pieces of inserts packed in a box, easy to store

Oscarbide 10 Pieces/Set,Milling Inserts Apkt Style Carbide Cutters

- APKT1604PDFR-MA carbide inserts,0.2 Radius.

- Made of Tungsten Carbide,the cutting speed are 4-7 time faster than generic steel,and Sharpened on a diamond wheel to make it longer tool life, providing you a better experience and durable use and Better cut

- Designed for non-ferrous metal,high-silicon aluminum alloy

- Used for Face Milling Cutter Aluminum Cutting Tools Machining Aluminum

- 10pcs With a plastic box for convenient storage