Uxcell A22022400UX0577 T-Slot Milling Cutters

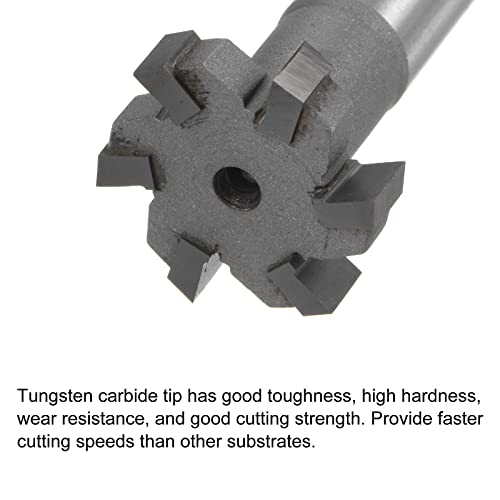

- T-Slot Cutters - Cutting Dia. - 25mm / 0.98"; Cutting Depth - 3mm / 0.12"; Shank Dia. - 12mm / 0.47"; Total Length - 100mm / 3.94"; Number of Flutes - 6 Flutes. Tungsten carbide tip has good toughness, high hardness, wear resistance, and good cutting strength. Provide faster cutting speeds than other substrates.

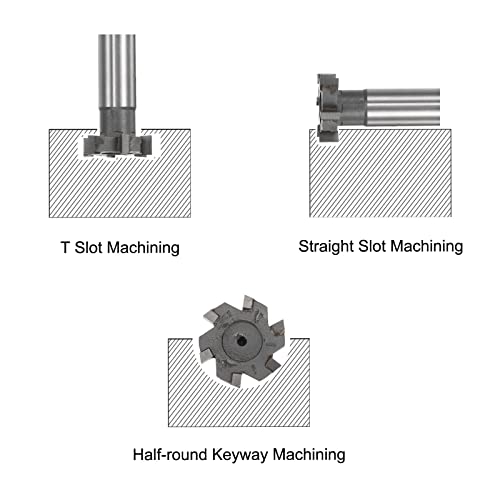

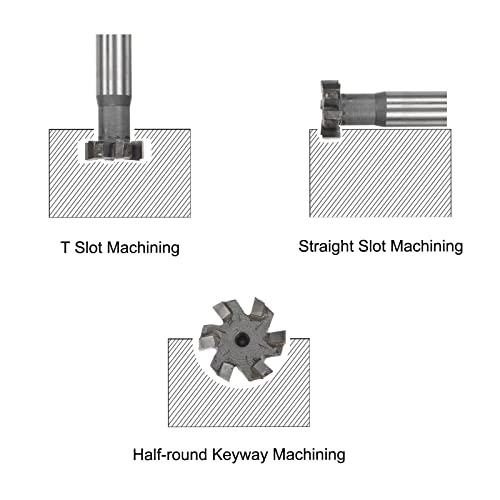

- Wide Applications - Suitable for machining T slotting, straight slotting, side grooving and half-round keyway on the work piece. Widely used for milling stainless steel, carbon steel, alloy steel, copper, tool steel, cast iron, aluminum, etc..

- Features - The cutting edge is sharp and not easy to break. High-frequency welding process is adopted for the connection between the cutter head and the cutter body. Universal chamfered round shank, easier clamping, stable cutting process.

- Easy to Use - Used on drilling and milling machines, machining centers. Properly reduce the cutting speed and feed can prolong the life of the milling cutter. Add cutting fluid to protect the cutting edge and make the cutting smoother when working.

- Tips - The longer the length of the tool clamped by the chuck, the better. If the clamping length is shorter, you need to lower the feed rate and cutting speed to reduce vibration and extend the tool life.

Uxcell A22022400UX0580 T-Slot Milling Cutters

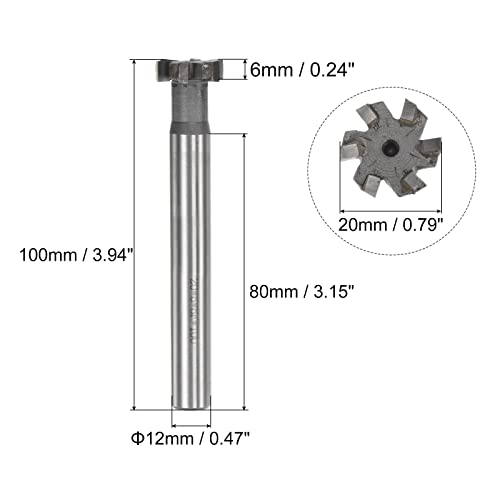

- T-Slot Cutters - Cutting Dia. - 25mm / 0.98"; Cutting Depth - 6mm / 0.24"; Shank Dia. - 12mm / 0.47"; Total Length - 100mm / 3.94"; Number of Flutes - 6 Flutes. Tungsten carbide tip has good toughness, high hardness, wear resistance, and good cutting strength. Provide faster cutting speeds than other substrates.

- Wide Applications - Suitable for machining T slotting, straight slotting, side grooving and half-round keyway on the work piece. Widely used for milling stainless steel, carbon steel, alloy steel, copper, tool steel, cast iron, aluminum, etc..

- Features - The cutting edge is sharp and not easy to break. High-frequency welding process is adopted for the connection between the cutter head and the cutter body. Universal chamfered round shank, easier clamping, stable cutting process.

- Easy to Use - Used on drilling and milling machines, machining centers. Properly reduce the cutting speed and feed can prolong the life of the milling cutter. Add cutting fluid to protect the cutting edge and make the cutting smoother when working.

- Tips - The longer the length of the tool clamped by the chuck, the better. If the clamping length is shorter, you need to lower the feed rate and cutting speed to reduce vibration and extend the tool life.

Uxcell A22022400UX0566 T-Slot Milling Cutters

- T-Slot Cutters - Cutting Dia. - 16mm / 0.63"; Cutting Depth - 6mm / 0.24"; Shank Dia. - 10mm / 0.39"; Total Length - 80mm / 3.15"; Number of Flutes - 4 Flutes. Tungsten carbide tip has good toughness, high hardness, wear resistance, and good cutting strength. Provide faster cutting speeds than other substrates.

- Wide Applications - Suitable for machining T slotting, straight slotting, side grooving and half-round keyway on the work piece. Widely used for milling stainless steel, carbon steel, alloy steel, copper, tool steel, cast iron, aluminum, etc..

- Features - The cutting edge is sharp and not easy to break. High-frequency welding process is adopted for the connection between the cutter head and the cutter body. Universal chamfered round shank, easier clamping, stable cutting process.

- Easy to Use - Used on drilling and milling machines, machining centers. Properly reduce the cutting speed and feed can prolong the life of the milling cutter. Add cutting fluid to protect the cutting edge and make the cutting smoother when working.

- Tips - The longer the length of the tool clamped by the chuck, the better. If the clamping length is shorter, you need to lower the feed rate and cutting speed to reduce vibration and extend the tool life.

Uxcell A22022400UX0563 T-Slot Milling Cutters

- T-Slot Cutters - Cutting Dia. - 16mm / 0.63"; Cutting Depth - 3mm / 0.12"; Shank Dia. - 10mm / 0.39"; Total Length - 80mm / 3.15". Tungsten carbide tip has good toughness, high hardness, wear resistance, and good cutting strength. Provide faster cutting speeds than other substrates.

- Wide Applications - Suitable for machining T slotting, straight slotting, side grooving and half-round keyway on the work piece. Widely used for milling stainless steel, carbon steel, alloy steel, copper, tool steel, cast iron, aluminum, etc..

- Features - The cutting edge is sharp and not easy to break. High-frequency welding process is adopted for the connection between the cutter head and the cutter body. Universal chamfered round shank, easier clamping, stable cutting process.

- Easy to Use - Used on drilling and milling machines, machining centers. Properly reduce the cutting speed and feed can prolong the life of the milling cutter. Add cutting fluid to protect the cutting edge and make the cutting smoother when working.

- Tips - The longer the length of the tool clamped by the chuck, the better. If the clamping length is shorter, you need to lower the feed rate and cutting speed to reduce vibration and extend the tool life.

Klot 3-20 Altin Coated T Slot Keyseat Milling Cutter Solid Carbide 3Mm-20Mm T Slotting End Mill

Harfington HTA221011HH1509 T Slot End Mill Milling Cutter 4Mm Cutting 1.5Mm Depth 4Mm Shank Solid Carbide Titanium Coated 4 Flutes

- Size - Cutting diameter - 4mm / 0.16"; cutting depth - 1.5mm / 0.06"; shank diameter - 4mm / 0.16"; shank length - 36mm / 1.42"; total length - 50mm / 1.97"; number of flutes - 4 flutes

- Material - The solid carbide T-slot milling cutter has has high hardness (HRC92), good toughness, wear resistance, bending resistance and heat resistance. With good milling and cutting performance, carbide can run at higher speed than other substrates.

- Features - Sharp cutting edge provides smooth cutting, not easy to break. Titanium coating provides excellent corrosion resistance, greatly improves wear resistance and hardness, and reduces the coefficient of friction.

- Applications - Suitable for machining T slotting, straight slotting, side grooving and half-round keyway on the work piece. Widely used for milling and cutting stainless steel, cast iron, tool steel, alloy steel, copper, aluminum, composite materials, etc.

- Notes - Used on CNC machining centers, drilling and milling machines, engraving machines. Properly reduce the cutting speed and feed can prolong the life of the milling cutter. Add cutting fluid to protect the cutting edge and make the cutting smoother when working.

Nacx C341-344 Hss-Al T Slot End Mill Milling Cutter,High-Speed Steel Woodruff Keyseat Cutter

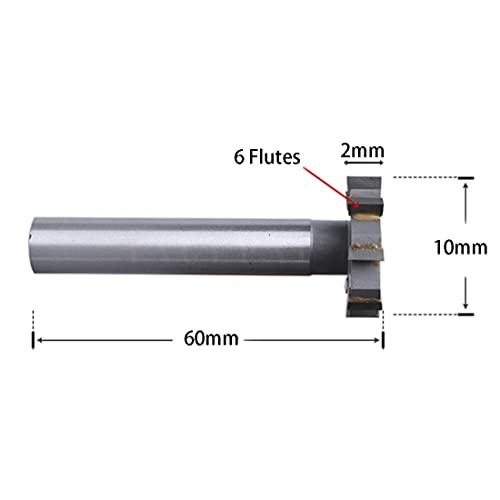

- Size - Cutting Diameter - 10mm/ 0.39"; Cutting Depth - 2mm/ 0.07"; Number of Flutes - 6; Total Length - 60mm/ 2.36".

- Advantages - The cutting edge is sharp and wear-resistant, it is not easy to break the edge, the surface is clean and free of burrs, and the finished workpiece has a high finish.

- Material - This T-slot end mill is made of high-quality high-speed steel (HSSAL) material, which is wear-resistant and not easy to stick to the tool.

- Durability - The joint of the cutter head and the cutter body adopts high-frequency welding technology, which is durable and not easy to break the cutter, which greatly improves the practical life of the cutter.

- Application - Used for processing T-slots on various mechanical workbenches or other structures. Suitable for milling steel, aluminum, copper, iron and non-ferrous metal materials.

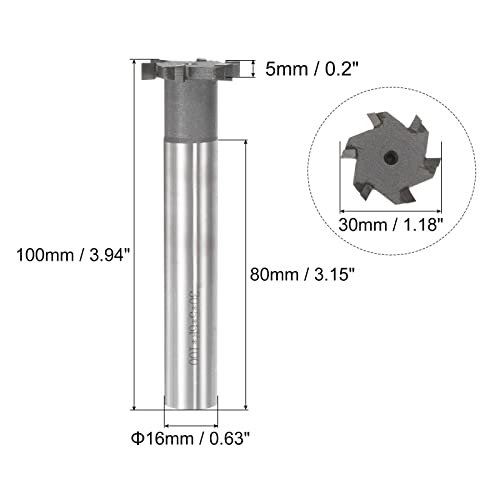

Uxcell A22022400UX0588 T-Slot Milling Cutters

- T-Slot Cutters - Cutting Dia. - 30mm / 1.18"; Cutting Depth - 8mm / 0.31"; Shank Dia. - 16mm / 0.63"; Total Length - 100mm / 3.94"; Number of Flutes - 6 Flutes. Tungsten carbide tip has good toughness, high hardness, wear resistance, and good cutting strength. Provide faster cutting speeds than other substrates.

- Wide Applications - Suitable for machining T slotting, straight slotting, side grooving and half-round keyway on the work piece. Widely used for milling stainless steel, carbon steel, alloy steel, copper, tool steel, cast iron, aluminum, etc..

- Features - The cutting edge is sharp and not easy to break. High-frequency welding process is adopted for the connection between the cutter head and the cutter body. Universal chamfered round shank, easier clamping, stable cutting process.

- Easy to Use - Used on drilling and milling machines, machining centers. Properly reduce the cutting speed and feed can prolong the life of the milling cutter. Add cutting fluid to protect the cutting edge and make the cutting smoother when working.

- Tips - The longer the length of the tool clamped by the chuck, the better. If the clamping length is shorter, you need to lower the feed rate and cutting speed to reduce vibration and extend the tool life.

Uxcell A22022400UX0569 T-Slot Milling Cutters

- T-Slot Cutters - Cutting Dia. - 20mm / 0.79"; Cutting Depth - 3mm / 0.12"; Shank Dia. - 12mm / 0.47"; Total Length - 100mm / 3.94"; Number of Flutes - 6 Flutes. Tungsten carbide tip has good toughness, high hardness, wear resistance, and good cutting strength. Provide faster cutting speeds than other substrates.

- Wide Applications - Suitable for machining T slotting, straight slotting, side grooving and half-round keyway on the work piece. Widely used for milling stainless steel, carbon steel, alloy steel, copper, tool steel, cast iron, aluminum, etc..

- Features - The cutting edge is sharp and not easy to break. High-frequency welding process is adopted for the connection between the cutter head and the cutter body. Universal chamfered round shank, easier clamping, stable cutting process.

- Easy to Use - Used on drilling and milling machines, machining centers. Properly reduce the cutting speed and feed can prolong the life of the milling cutter. Add cutting fluid to protect the cutting edge and make the cutting smoother when working.

- Tips - The longer the length of the tool clamped by the chuck, the better. If the clamping length is shorter, you need to lower the feed rate and cutting speed to reduce vibration and extend the tool life.

Harfington HTA221011HH1518 T Slot End Mill Milling Cutter 6Mm Cutting 3Mm Depth 6Mm Shank Solid Carbide Titanium Coated 4 Flutes

- Size - Cutting diameter - 6mm / 0.24"; cutting depth - 3mm / 0.12"; shank diameter - 6mm / 0.24"; shank length - 32mm / 1.26"; total length - 50mm / 1.97"; number of flutes - 4 flutes

- Material - The solid carbide T-slot milling cutter has has high hardness (HRC92), good toughness, wear resistance, bending resistance and heat resistance. With good milling and cutting performance, carbide can run at higher speed than other substrates.

- Features - Sharp cutting edge provides smooth cutting, not easy to break. Titanium coating provides excellent corrosion resistance, greatly improves wear resistance and hardness, and reduces the coefficient of friction.

- Applications - Suitable for machining T slotting, straight slotting, side grooving and half-round keyway on the work piece. Widely used for milling and cutting stainless steel, cast iron, tool steel, alloy steel, copper, aluminum, composite materials, etc.

- Notes - Used on CNC machining centers, drilling and milling machines, engraving machines. Properly reduce the cutting speed and feed can prolong the life of the milling cutter. Add cutting fluid to protect the cutting edge and make the cutting smoother when working.

Uxcell A22022400UX0578 T-Slot Milling Cutters

- T-Slot Cutters - Cutting Dia. - 25mm / 0.98"; Cutting Depth - 4mm / 0.16"; Shank Dia. - 12mm / 0.47"; Total Length - 100mm / 3.94"; Number of Flutes - 6 Flutes. Tungsten carbide tip has good toughness, high hardness, wear resistance, and good cutting strength. Provide faster cutting speeds than other substrates.

- Wide Applications - Suitable for machining T slotting, straight slotting, side grooving and half-round keyway on the work piece. Widely used for milling stainless steel, carbon steel, alloy steel, copper, tool steel, cast iron, aluminum, etc..

- Features - The cutting edge is sharp and not easy to break. High-frequency welding process is adopted for the connection between the cutter head and the cutter body. Universal chamfered round shank, easier clamping, stable cutting process.

- Easy to Use - Used on drilling and milling machines, machining centers. Properly reduce the cutting speed and feed can prolong the life of the milling cutter. Add cutting fluid to protect the cutting edge and make the cutting smoother when working.

- Tips - The longer the length of the tool clamped by the chuck, the better. If the clamping length is shorter, you need to lower the feed rate and cutting speed to reduce vibration and extend the tool life.

Uxcell A22022400UX0573 T-Slot Milling Cutters

- T-Slot Cutters - Cutting Dia. - 20mm / 0.79"; Cutting Depth - 8mm / 0.31"; Shank Dia. - 12mm / 0.47"; Total Length - 100mm / 3.94"; Number of Flutes - 6 Flutes. Tungsten carbide tip has good toughness, high hardness, wear resistance, and good cutting strength. Provide faster cutting speeds than other substrates.

- Wide Applications - Suitable for machining T slotting, straight slotting, side grooving and half-round keyway on the work piece. Widely used for milling stainless steel, carbon steel, alloy steel, copper, tool steel, cast iron, aluminum, etc..

- Features - The cutting edge is sharp and not easy to break. High-frequency welding process is adopted for the connection between the cutter head and the cutter body. Universal chamfered round shank, easier clamping, stable cutting process.

- Easy to Use - Used on drilling and milling machines, machining centers. Properly reduce the cutting speed and feed can prolong the life of the milling cutter. Add cutting fluid to protect the cutting edge and make the cutting smoother when working.

- Tips - The longer the length of the tool clamped by the chuck, the better. If the clamping length is shorter, you need to lower the feed rate and cutting speed to reduce vibration and extend the tool life.

Harfington HTA221011HH1537 T Slot End Mill Milling Cutter 6Mm Cutting 2.5Mm Depth 6Mm Shank Solid Carbide 3 Flutes

- Size - Cutting diameter - 6mm / 0.24"; cutting depth - 2.5mm / 0.1"; shank diameter - 6mm / 0.24"; shank length - 32mm / 1.26"; total length - 50mm / 1.97"; number of flutes - 3 flutes

- Material - The solid carbide T-slot milling cutter has has high hardness (HRC92), good toughness, wear resistance, bending resistance and heat resistance. With good milling and cutting performance, carbide can run at higher speed than other substrates.

- Features - Sharp cutting edge provides smooth cutting, not easy to break. Designed with the base substrate without any coatings, good for general purpose milling. Universal round shank can de used with a wide variety of tool holding system.

- Applications - Suitable for machining T slotting, straight slotting, side grooving and half-round keyway on the work piece. Widely used for milling and cutting aluminum, copper, die-cast aluminum, zinc alloy, plastic, etc.

- Notes - Used on CNC machining centers, drilling and milling machines, engraving machines. Properly reduce the cutting speed and feed can prolong the life of the milling cutter. Add cutting fluid to protect the cutting edge and make the cutting smoother when working.

Uxcell A22022400UX0572 T-Slot Milling Cutters

- T-Slot Cutters - Cutting Dia. - 20mm / 0.79"; Cutting Depth - 6mm / 0.24"; Shank Dia. - 12mm / 0.47"; Total Length - 100mm / 3.94"; Number of Flutes - 6 Flutes. Tungsten carbide tip has good toughness, high hardness, wear resistance, and good cutting strength. Provide faster cutting speeds than other substrates.

- Wide Applications - Suitable for machining T slotting, straight slotting, side grooving and half-round keyway on the work piece. Widely used for milling stainless steel, carbon steel, alloy steel, copper, tool steel, cast iron, aluminum, etc..

- Features - The cutting edge is sharp and not easy to break. High-frequency welding process is adopted for the connection between the cutter head and the cutter body. Universal chamfered round shank, easier clamping, stable cutting process.

- Easy to Use - Used on drilling and milling machines, machining centers. Properly reduce the cutting speed and feed can prolong the life of the milling cutter. Add cutting fluid to protect the cutting edge and make the cutting smoother when working.

- Tips - The longer the length of the tool clamped by the chuck, the better. If the clamping length is shorter, you need to lower the feed rate and cutting speed to reduce vibration and extend the tool life.

Uxcell A22022400UX0571 T-Slot Milling Cutters

- T-Slot Cutters - Cutting Dia. - 20mm / 0.79"; Cutting Depth - 5mm / 0.2"; Shank Dia. - 12mm / 0.47"; Total Length - 100mm / 3.94"; Number of Flutes - 6 Flutes. Tungsten carbide tip has good toughness, high hardness, wear resistance, and good cutting strength. Provide faster cutting speeds than other substrates.

- Wide Applications - Suitable for machining T slotting, straight slotting, side grooving and half-round keyway on the work piece. Widely used for milling stainless steel, carbon steel, alloy steel, copper, tool steel, cast iron, aluminum, etc..

- Features - The cutting edge is sharp and not easy to break. High-frequency welding process is adopted for the connection between the cutter head and the cutter body. Universal chamfered round shank, easier clamping, stable cutting process.

- Easy to Use - Used on drilling and milling machines, machining centers. Properly reduce the cutting speed and feed can prolong the life of the milling cutter. Add cutting fluid to protect the cutting edge and make the cutting smoother when working.

- Tips - The longer the length of the tool clamped by the chuck, the better. If the clamping length is shorter, you need to lower the feed rate and cutting speed to reduce vibration and extend the tool life.

Uxcell A18103100UX0380 Hss-Al T Slot End Mill Milling Cutter 8 Flutes 32Mm Cutting Dia 10Mm Depth

Uxcell A18103100UX0372 Hssal T Slot End Mill Milling Cutter 6 Flutes 16Mm Cutting Dia 4Mm Depth

Cocud CUF240110DD002230EU T-Slot Milling Cutters

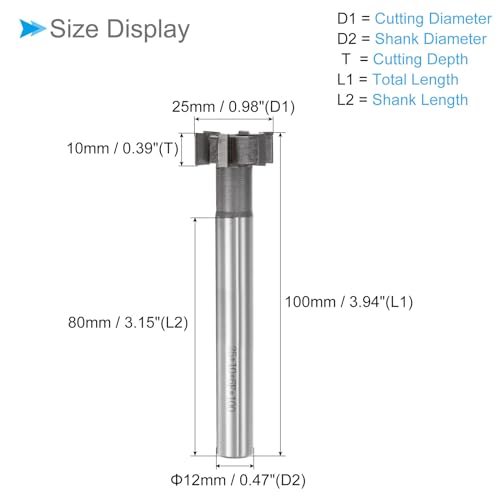

- T-Slot Milling Cutters Size -- Cutting Diameter - 25mm / 0.98", Cutting Depth - 10mm / 0.39", Shank Diameter - 12mm / 0.47", Shank Length - 80mm / 3.15", Total Length - 100mm / 3.94", Number of Flutes - 6 Flutes.

- Wide Applications - - Widely used in factories, workshops, special equipment manufacturing, etc. Suitable for processing T-shaped grooves, straight grooves, side grooves and semi-circular keyways on workpieces. Widely used for milling stainless steel, carbon steel, alloy steel, copper, tool steel, cast iron, aluminum, etc.

- Universal Chamfered Round Shank - - Universal chamfered round shank makes clamping easier and the cutting process more stable. The cutting edge is sharp and difficult to break, and provides faster cutting speeds than other substrates.

- Tungsten Carbide, High Speed Steel - - Made of tungsten carbide and high speed steel, ensuring high hardness, heat resistance and wear resistance. The high-frequency welding process is used to strengthen the connection between the cutter head and the cutter body.

- Useful Tips - - Adding cutting fluid can protect the cutting edge and make cutting smoother during work.

Uxcell A22022400UX0586 T-Slot Milling Cutters

- T-Slot Cutters - Cutting Dia. - 30mm / 1.18"; Cutting Depth - 5mm / 0.2"; Shank Dia. - 16mm / 0.63"; Total Length - 100mm / 3.94"; Number of Flutes - 6 Flutes. Tungsten carbide tip has good toughness, high hardness, wear resistance, and good cutting strength. Provide faster cutting speeds than other substrates.

- Wide Applications - Suitable for machining T slotting, straight slotting, side grooving and half-round keyway on the work piece. Widely used for milling stainless steel, carbon steel, alloy steel, copper, tool steel, cast iron, aluminum, etc..

- Features - The cutting edge is sharp and not easy to break. High-frequency welding process is adopted for the connection between the cutter head and the cutter body. Universal chamfered round shank, easier clamping, stable cutting process.

- Easy to Use - Used on drilling and milling machines, machining centers. Properly reduce the cutting speed and feed can prolong the life of the milling cutter. Add cutting fluid to protect the cutting edge and make the cutting smoother when working.

- Tips - The longer the length of the tool clamped by the chuck, the better. If the clamping length is shorter, you need to lower the feed rate and cutting speed to reduce vibration and extend the tool life.

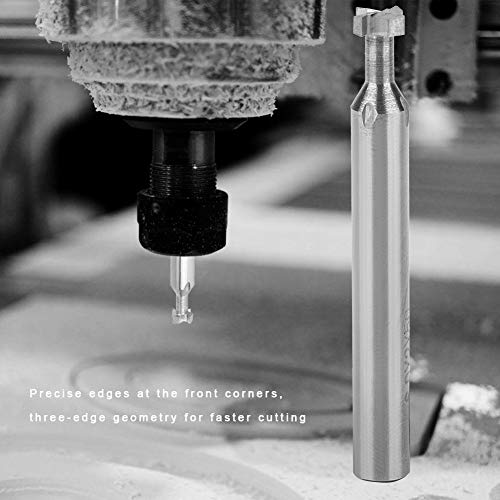

Walfront WALFRONTUPINS3TKG2 T Slot Cutter End Mill

- Good Durability Anti-stick Material - This T Slot Cutter End Mill is made of high quality tungsten steel material, wear resistant and not easy to stick cutter

- Good Durability Anti-stick Material - This T Slot Cutter End Mill is made of high quality tungsten steel material, wear resistant and not easy to stick cutter

- Offers Glossy and Cutting - Chamfering at the bottom, high smoothness and high overall precision

- High Efficiency Performance - Fast processing speed, high finish, strong continuous processing is not easy to break

- Three- Design Provides Faster Working - edges at the front corners, three- geometry for faster cutting

- HRC55 - Suitable for objects with hardness lower than HRC55